- Home

- Composite Cladding

- WEO® 35 composite cladding

WEO® 35 composite cladding

An open-joint profile guaranteed free from fading

- Modern open-joint appearance

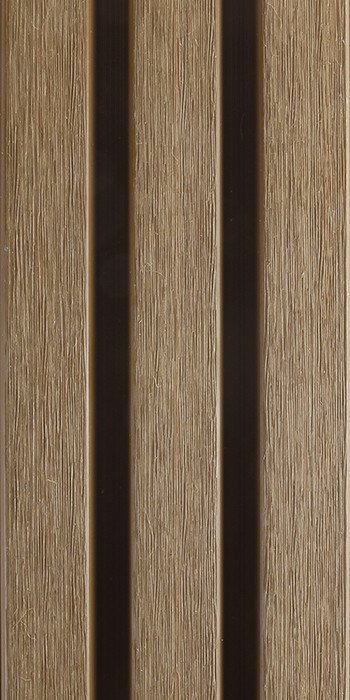

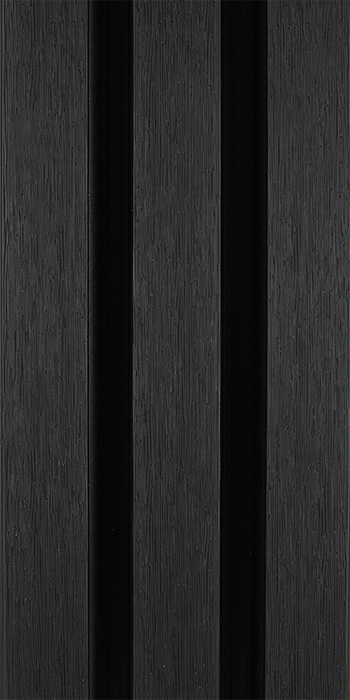

- Exceptional natural wood imitation

- Colour guaranteed for 20 years

- Multi-chromatic colours

- Easy to install

WEO 35 composite cladding Installation

48-72h delivery

Characteristics

DELTA E = 1.09

- Co-extrusion layer

- Hollow profile

- Tongue and groove assembly

The advantage of a remarkable and durable wood appearance

Wood cladding: warm but too expensive to maintain? The solution is WEO® composite cladding!

Developed with the latest extrusion technologies, WEO® composite cladding combines the durability of co-extrusion and the warm appearance of wood. The false open-joint profile, trendy and modern, gives rhythm to the façade while preserving the natural character and warmth of wood. Random nuances in colours reinforce the realistic impression of a natural, untreated material.

For many individuals, the composite solution is ideal for all types of projects (renovation or new deck)

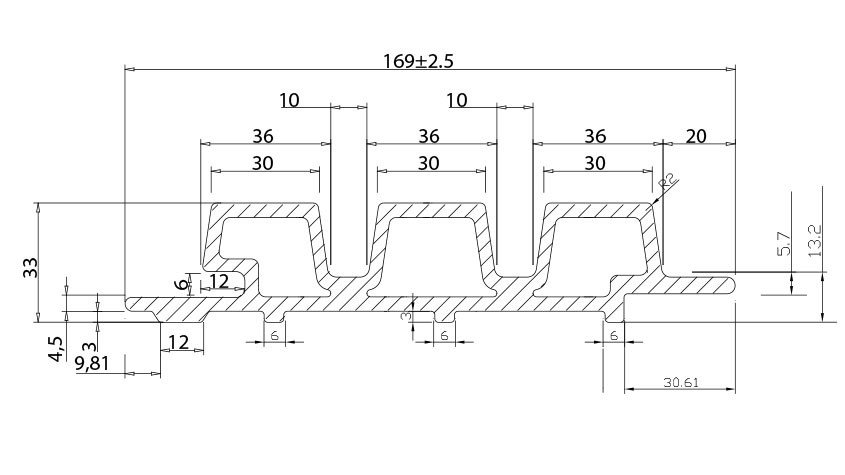

A stable cell profile with lugs

The WEO® profile is stabilized thanks to its underside, or backing.

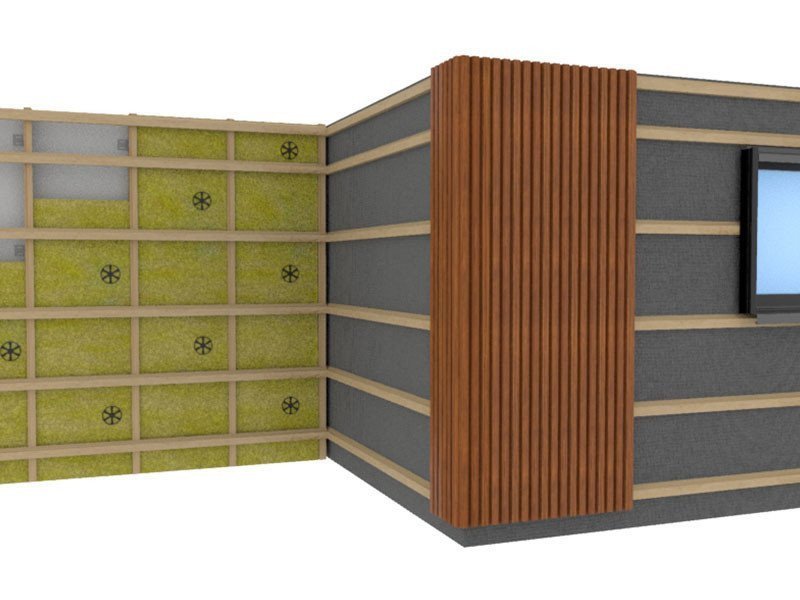

The WEO® composite cladding structure is equipped with lugs on the backs of boards, which naturally create a thin space for air between the support and the siding. In vertical installations, they help install boards on a simple wood or metal frame only. Another advantage, the WEO® board coating is rot-proof and has no risk of any moisture pick-up. Air circulation is only for ventilation of the support.

Modern and trendy profile

Offered in a unique false open-joint profile, WEO® cladding is resolutely modern and attractive. Boards with distinct embossed designs break the uniform and regular rhythm of façades. The pronounced trapezoidal wave shape ensures good rain water run-off. These composite panels also perfectly imitate the open-joint appearance of wood cladding!

Two possible installation choices - vertical or horizontal - accentuate the perception of height or depth for exterior façades.

QB : Quality Building– certification mark of the CSTB

Our cladding product WEO35 is certified QB-15 by the CSTB under the certification number 143-154 The QB certifies the compliance of WEO35 cladding with conditions set out in the CSTB certification reference systems.

These conditions come from commonly accepted standards by industrias. In addition, it includes additional requirements that take into account the needs of users and contractors.

ATEx : Technical Experimentation Assessment

Our cladding product WEO35 is covered by the ATEx, under CSTB reference number : 2846_V1 . WEO35 has benefited from a technical assessment carried out by a group of experts. This assessment provides preliminary feedback on the implementation of WEO35 cladding, prior to a Technical Appraisal

Screws for WEO® composite cladding

WEO® composite cladding boards are very easily installed using their groove-tab nesting system. They fasten on wood or metal frameworks by simple screwing in the wave base using self-drilling screws that are the same colour as the boards. This simple, quick system not only adjusts the boards by setting the nesting depth but also provides very discreet fastening of boards for a nearly invisible finish.

The replacement of a composite board is also extremely simple, which facilitates maintenance operations. The centre-to-centre distance between supports is 40 cm or 60 cm depending on the external façade exposure.

WEO SR2 stainless steel screws, 4.2 x 38 mm, are provided with panels. For wood or metal framework fasteners, please refer to specialists such as ETANCO or SFS INTEC

Coloured head stainless steel screws

The selected stainless steel screws for WEO® cladding fasteners are nearly invisible thanks to their colour (same as boards). Fasteners in the wave base blend into the facing. The screw fasteners make it possible to very easily adjust the gap between two boards with clips only.

A 20 year no-fading guarantee!

The WEO® composite cladding ensures excellent resistance in outside applications, thanks to its coating applied on the surface. This polyethylene-based waterproof film considerably reduces façade maintenance and maintains board colour over time: UV-resistant and non-porous, it ensures complete resistance to weather and other outdoor attacks, which weaken finishes and the original appearances of traditional cladding. Boards retain all of their aesthetic properties over time!

A 20 year no-fading guarantee!

The cell profile makes the boards lights and easy to handle during installation. Boards are thus totally compatible with installation on External Thermal Insulation Composite Systems (ETICS) and adapt to all insulation systems (e.g. RedAir System). WEO® composite cladding is also appropriate for renovations, extensions, single-family homes, residential buildings or public-access buildings. Consult your tradesman to learn about cladding prices and to get more information about its installation.

The composite material used in manufacturing WEO® cladding is 95% from recycled products and is 100% recyclable. The polymer (HDPE) results from reprocessing of plastic waste (plastic bottles). The wood particles come from wood industry recycling.

With no toxic products or VOC emission risk, WEO® cladding is perfectly safe for the user’s environment.

WEO® products constitute a pertinent eco-friendly alternative to tropical woods.